We help as little or as much as you need.

Check out what we do below.

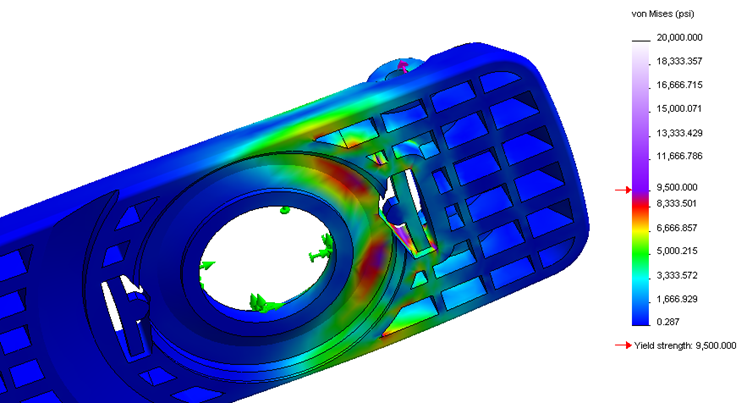

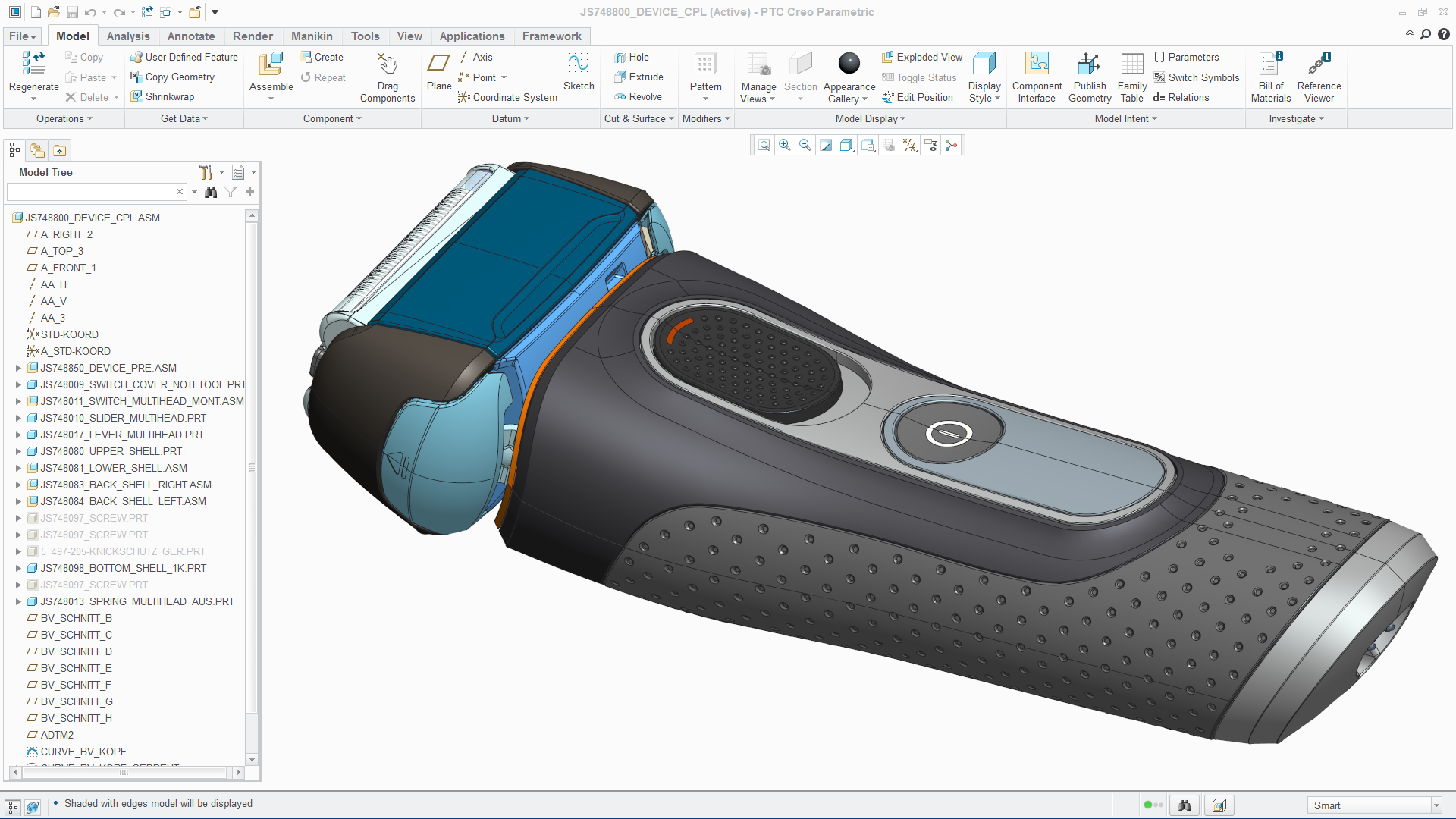

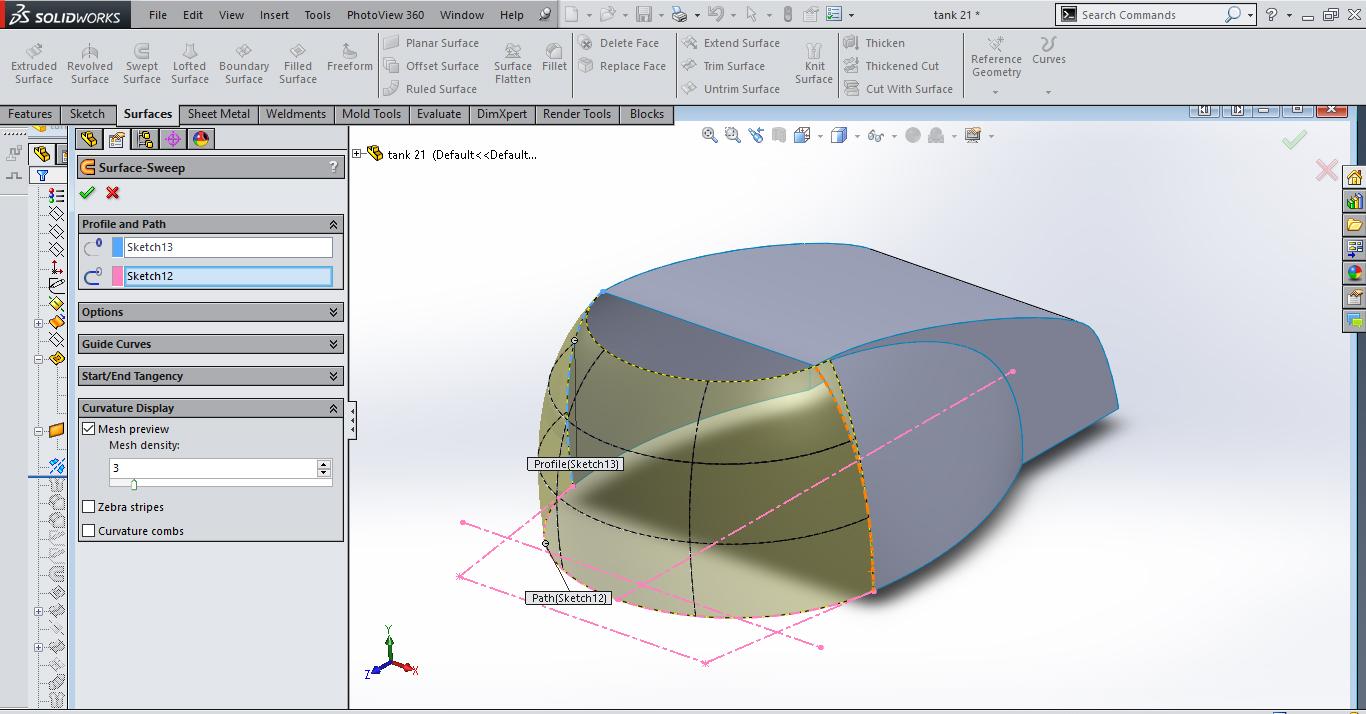

ENGINEERING

♦ Mechanical, Software and Electrical engineering

♦ CAD Modeling: Creo (Pro/Engineer) and Solidworks

♦ FEA (Finite Element Analysis)

♦ Model Simulation

♦ Design Optimization

♦ Technical Documentation for Manufacturing and Quality Assurance

♦ Quality Analysis

♦ Materials Selection

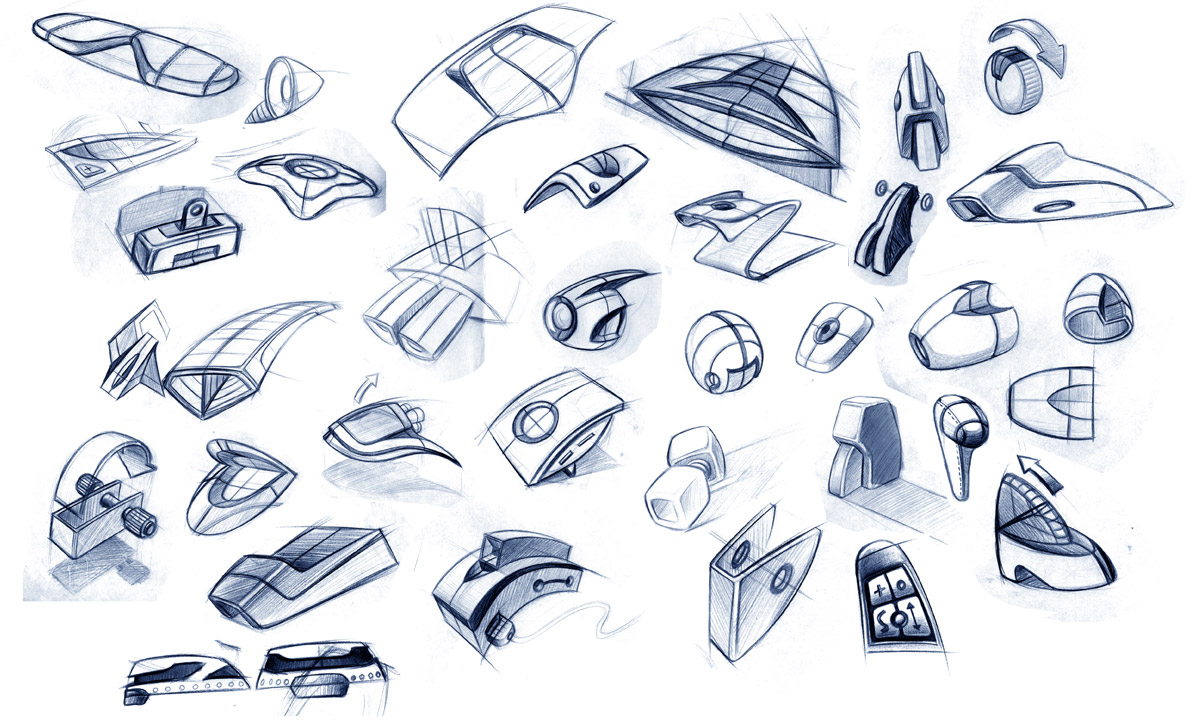

DESIGN

♦ Trend Analysis

♦ Ideation

♦ Concept development

♦ 2D & 3D Sketch Exploration

♦ Styling Exploration

♦ Color Studies Exploration

♦ Solid & Surface CAD Modeling

♦ Photo-realistic Rendering

♦ Presentation Rendering

♦ Packaging Illustration

♦ Product Marking/Graphics

PRODUCT ILLUSTRATION / PHOTO-REALISTIC RENDERINGS

♦ Photo-realistic renderings of CAD models

♦ Composite imaging with human interaction

♦ Package illustrations

♦ Combining real photography and CAD renderings

♦ Product-in-use Illustrations

♦ Point-of-purchase layout representations

♦ ‘Hero Shot’ of a pre-developed product

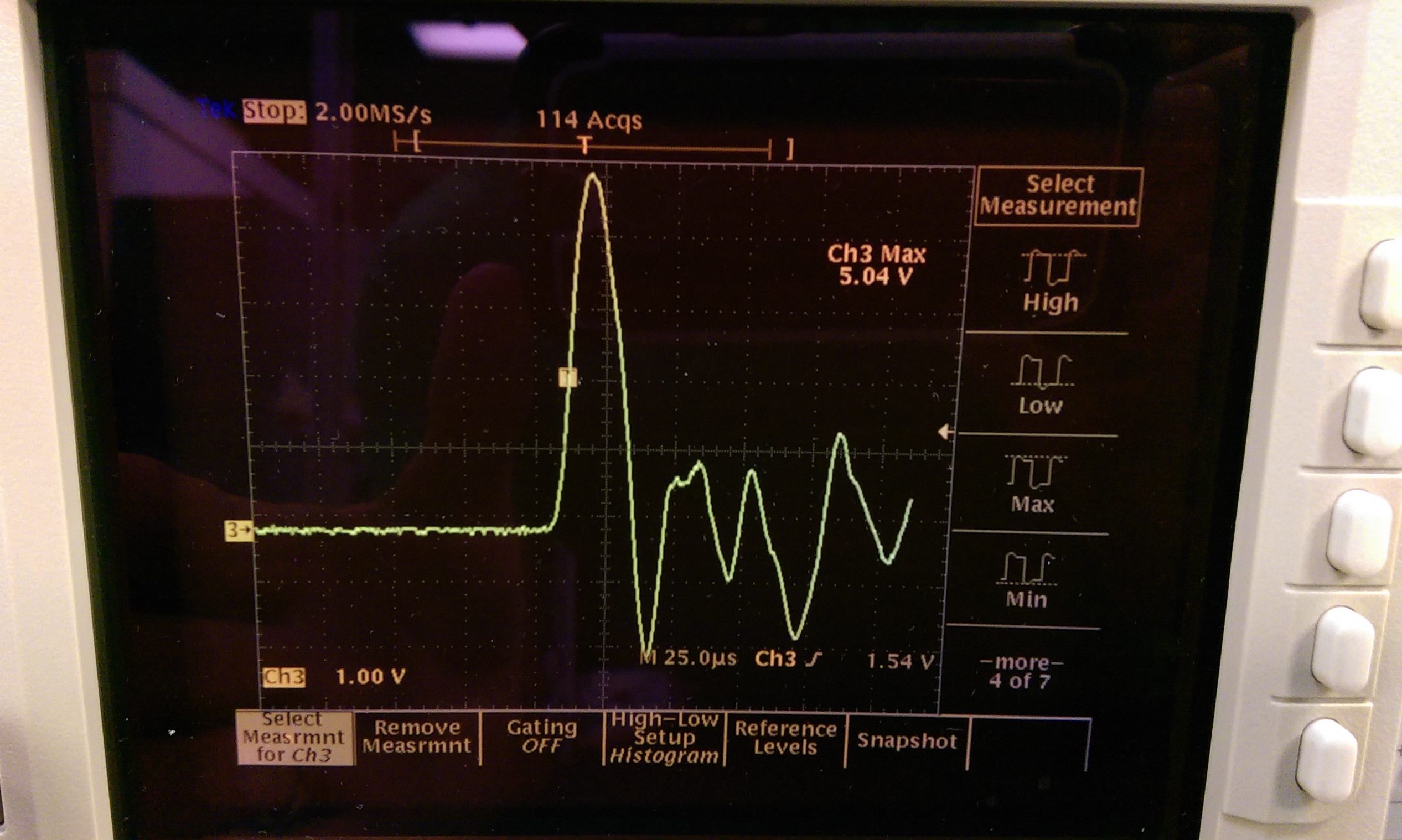

TESTING AND ANALYSIS

♦ Design Verification Testing (DVT)

♦ Accelerated Life Testing (ALT)

♦ Environmental (temp & vibration)

♦ Failure Analysis

♦ Regulatory Compliance Testing (FCC, CE)

♦ Ingress Protection (IP-XX) Tesing

♦ Impact Instrumentation and Testing

♦ Documentation of Test Procedure and Results

MANUFACTURING

♦ From small order quantities to over a million units per month.

♦ Reliable tooling - minimum down time.

♦ Plastics - We've been designing and manufacturing injection molded plastic components and assemblies for over two decades.

♦ In-mold-decoration

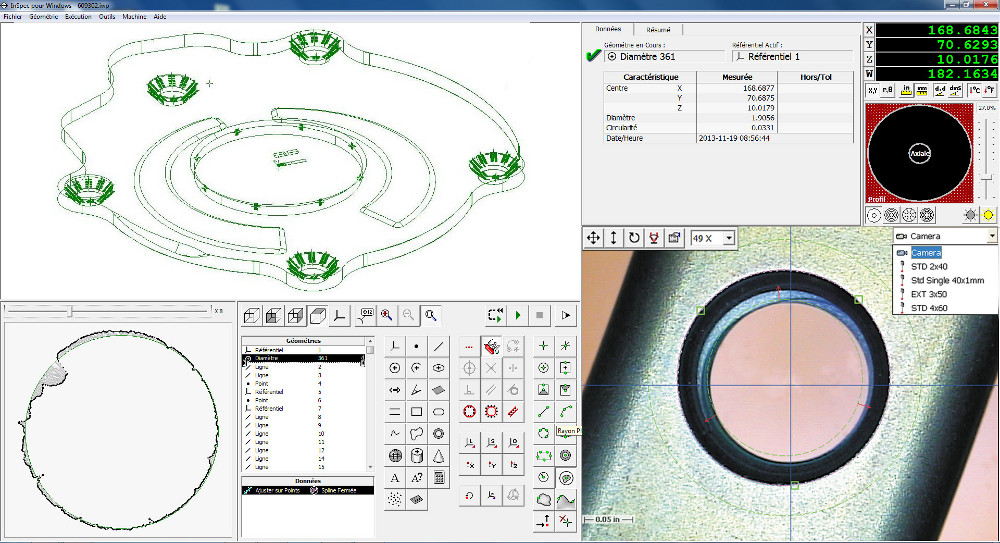

♦ High precision dimensional measurement equipment

♦ Electronics -we support prototype through medium/high volume manufacturing of circuit board assemblies.

♦ Surface mount (SMT), thru hole, wiring, and box build assembly.

♦ Double injection

♦ Retail packaging

♦ ISO standards and compliance

QUALITY ASSURANCE

♦ Production Part Approval Process (PPAP) - approve production design and processes before, during, and after manufacture

♦ Reliable tooling - minimum down time.

♦ High precision dimensional measurement equipment

♦ ISO standards and compliance

♦ Process Control

♦ Quality Assurance through design, process control, and measurement.

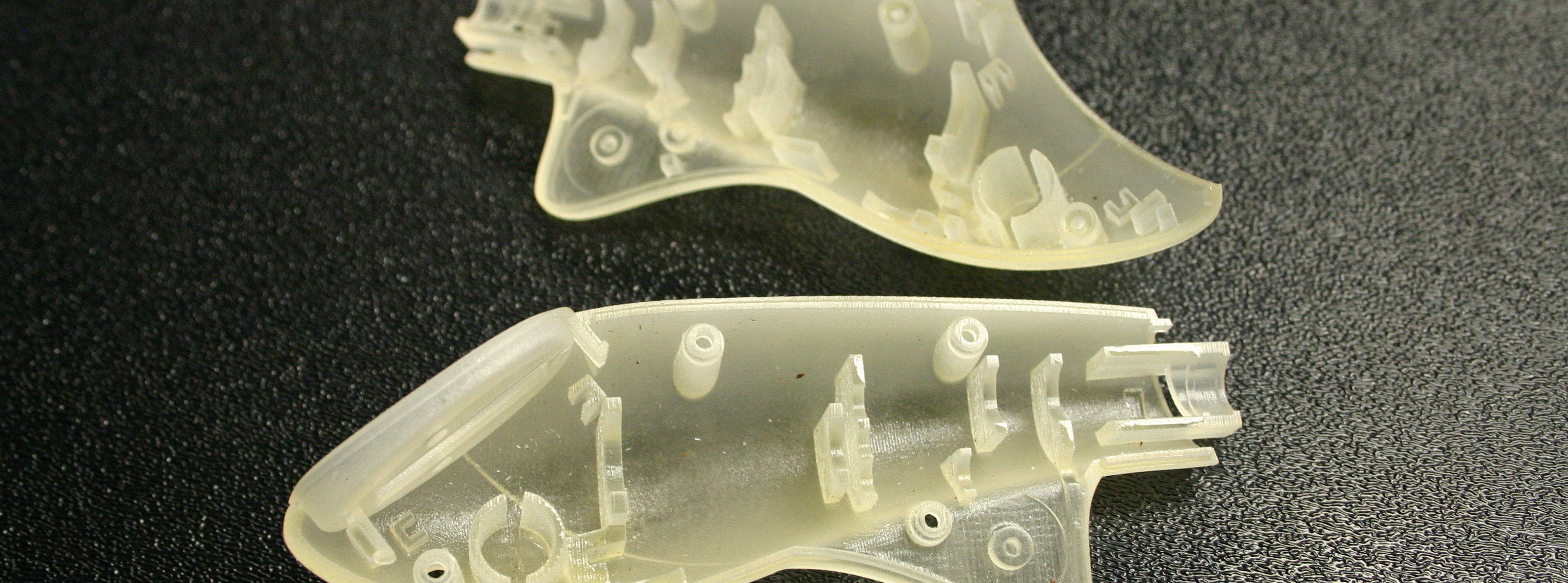

PROTOTYPING

♦ Proof-of-Principle - 3D printing (many resins and durometers)

♦ Working Prototype - Fine detail CNC machining using production intent materials.

♦ Visual Prototype - Colors, Materials, Finish (CMF)

♦ Functional/User experience - marketing quality